An intern’s tour of General Fusion

By Isaac Clemenger

After a summer interning with Fusion Energy Insights, I visited Vancouver, Canada, on holiday. While we were there, I and a couple of other physics students had the pleasure of seeing General Fusion’s lab in Richmond, British Columbia. We were given a tour by Kathryn Leci, a plasma injector engineer.

So, what did we see and what did we find interesting?

What we saw

Upon entering the lab, we first saw a small museum of past machines. It was interesting to see how much the shape of each device has changed throughout their development.

We also saw the initial proposed idea for compressing plasma, using pistons that fire acoustic hammers in specific timings to shape plasma into a sphere. Through testing on this machine, the company adjusted its approach and is now pursuing pneumatic pistons to shape a liquid metal liner to compress the plasma.

To see how this would work, watch this great video of their Founder and Chief Science Officer, Michel Laberge, explaining it.

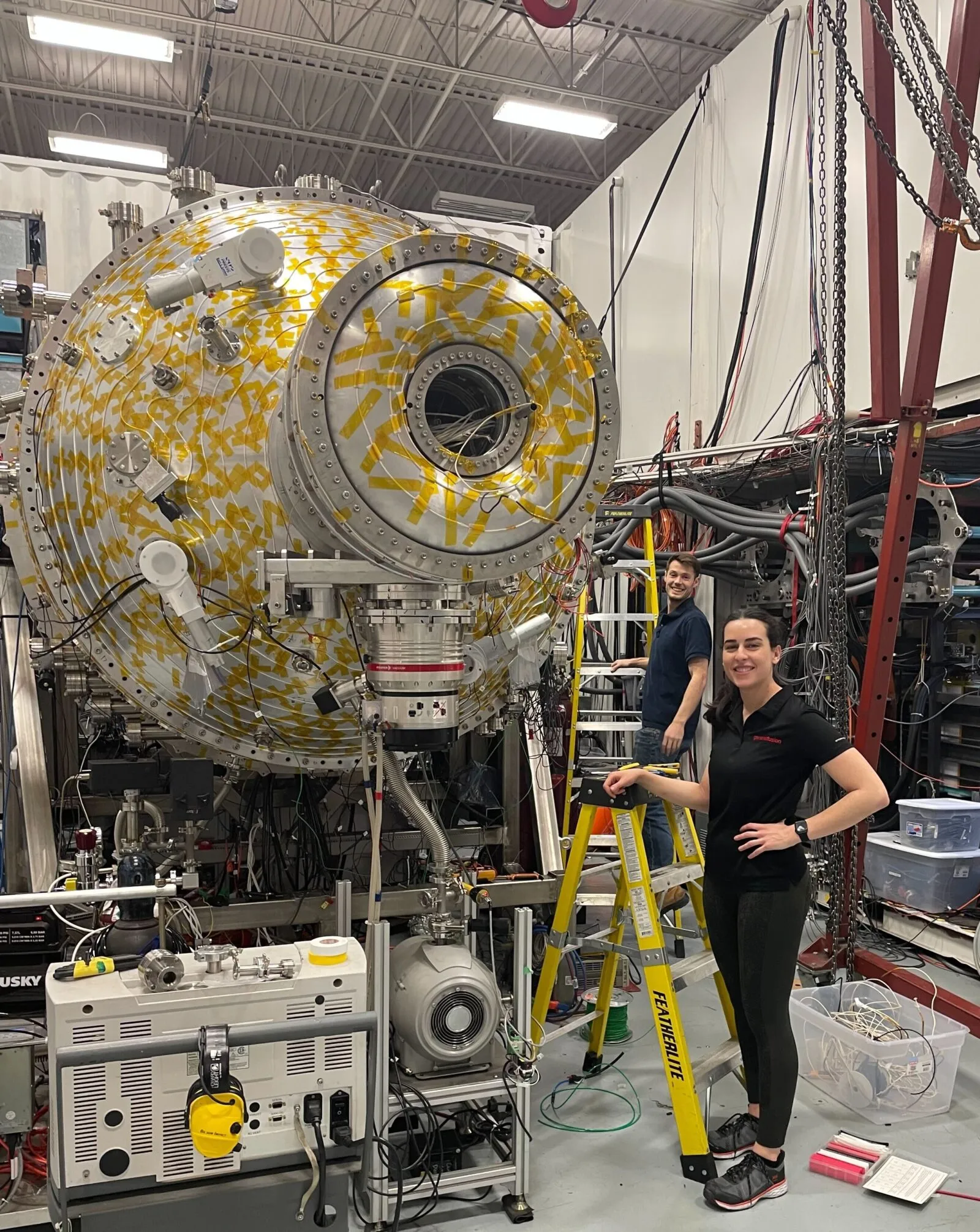

We were then led into another warehouse which houses their current plasma injector device. As there was no experiment running at the time, we were able to see the device close up, which felt quite surreal and gave us a great sense of the scale of the machine. This device is only designed to contain a mid-temperature plasma, not compress it to fusion conditions, which will take place in the newly announced LM26 device.

Our tour guide Kathryn Leci, said this about their current progress:

“Our focus is to continuously improve plasma performance by controlling key parameters like the magnetic configuration, pulsed power settings and machine wall condition.”

Finally, we went to a second warehouse where the scientists experiment on different compression technologies.

One approach consisted of electromagnetically compressing a lithium ring into a much smaller, but still perfectly symmetrical ring. The second approach was very similar but using liquid metal instead of solid lithium. This testing campaign provided valuable information needed for the next step—the shaped compression of solid lithium cylinders.

These prototypes de-risk the engineering of General Fusion’s compression design before it is installed onto the current plasma injector for their new device LM26, which aims to reach scientific breakeven in energy by 2026.

Kathryn Leci © General Fusion

What we found interesting

It was fascinating to see essentially all of the elements of LM26 in testing before they all come together, and to visually experience the design process of the device. LM26 will be built in Vancouver where the current fusion device is, and if they can succeed in their goal of breakeven by 2026 it will be a huge achievement.

More specific to the current fusion device, I thought the capacitor bank system was very interesting. The 6MJ of capacitor banks supply energy to the plasma before it is injected into the confinement chamber. They fire in 2 main stages: the formation stage; and shaft current stage.

In the formation stage, one pulse provides an initial ionisation to the plasma, and the other delivers the majority of the energy to the plasma to get it to the required temperature.

In the shaft current stage, the capacitor banks supply a current, inducing a toroidal magnetic field and shaping the plasma. There are two pulses here. The first always fires, but the second is optional and allows the engineers to repeat the experiment, modifying the shaft current’s settings to adjust the plasma’s shape.

The plasma injector (PI3) © General Fusion

What’s Next?

The next step for General Fusion is the LM26 device. They are targeting temperatures of 100 million degrees by 2025, and a scientific breakeven in energy by 2026. This would be a huge achievement if they succeeded and I am excited for what the future holds.

I want to give a huge thank you to General Fusion and Kathryn Leci for this amazing experience.

***