Japanese Helical Fusion: 3 Key Insights

Helical Fusion’s COO, Yusuke Kubo, joined us recently for a detailed Q&A for FEI Premium subscribers. We discussed the company’s progress in HTS magnet development, the unique advantages of the heliotron stellarator design and Japan’s emerging strategy to build a nationally-supported fusion industry.

Here are three key insights from the event.

1. The heliotron design gives the possibility of high performance with high uptime

A major engineering advantage of the heliotron is the size of its access ports for maintenance. The helical coil layout naturally creates large access ports, larger than in other stellarator designs. That makes it much easier to replace components, like blankets or divertors, because you can extract them directly through the upper port.

While stellarator families often differ mainly in coil geometry, this feature has meaningful implications for commercial operation.

“We think the helical stellarator has a little bit [of an] advantage on those kind of [replacement] operations and the maintenance, and so that makes plant uptime higher in commercial fusion,” said Kubo.

The result is a configuration that retains strong plasma performance while enabling easier servicing, reduced downtime and more predictable plant availability.

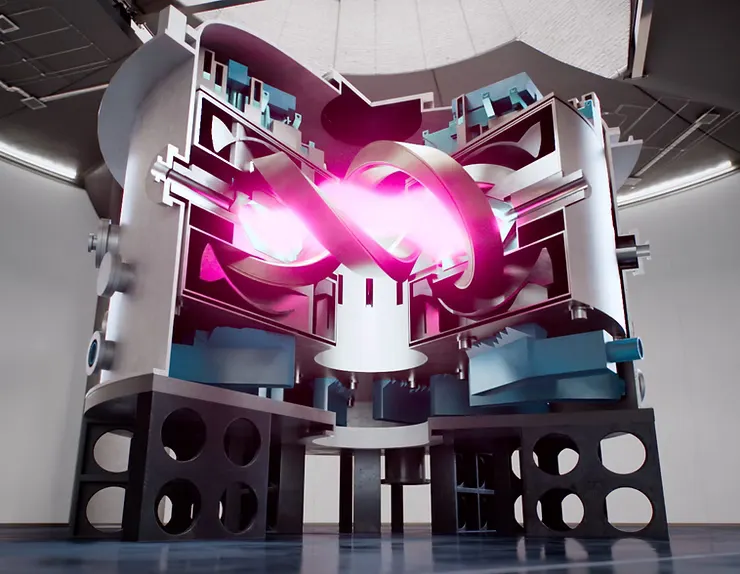

Helix KANATA – The world’s first steady-state net power fusion plant under development by Helical Fusion. ©Helical Fusion

2. The Helical Fusion integrated demonstration device, HARUKA, will use a liquid metal blanket to mitigate the higher heat loads due to the more compact design

Helical Fusion’s flexible high temperature superconductor (HTS) cable technology enables the tight, non-planar coil geometries needed for their compact stellarator. But, as Kubo noted, there is a downside of smaller machines:

“HTS magnets will make the fusion device compact. But the disadvantage of making it compact is that it would create high heat flux to be exhausted in the divertor sections.”

To manage this concentrated heat load, the team is developing a flowing liquid-metal blanket that serves not only as a tritium-breeding system but also as part of the plasma-facing surface.

The flowing liquid-metal blanket spreads the heat more effectively than solid materials.

For Helical Fusion, the compact design and the liquid blanket go hand in hand. Both technologies must work together.

Kubo: “What we were trying to do is to use liquid metal as a first wall—not only the [breeding] blanket system, but as a plasma facing component as well.

“So combining those two [technologies] is essential, that's why we are developing them in parallel.”

3. Japan is building a fusion industry through government leadership and industrial strength

Helical Fusion’s progress is strongly supported by Japan’s government and industrial base.

Their magnet campaign is supported through Japan’s SBIR Phase Three programme, which provided the equivalent of around US $15 million and allowed them to accelerate development.

Additionally, “we leverage Japanese industry,” said Kubo. “Behind Helical Fusion is Japan's industrial backbone—world class manufacturers, materials and precision engineering. With partners like Toshiba, Fuji Electric, IHI, Fujikura, Mitsui Kinzoku… we are turning craftsmanship into a new energy industry.”

This activity sits within a wider political shift:

“Ms Takaichi,” said Kubo, “just became Prime Minister a month ago…. But what she has already announced is that fusion will become a strategic area of her government, with new investment to boost Japanese economy.”

Helical Fusion combines practical engineering progress and deep industrial partnerships with growing national momentum as a promising contributor to Japan’s wider fusion ambition.

—-----------------------------------------------------------------------------------------------------------------------

Premium Subscribers of Fusion Energy Insights can watch the full replay of the Q&A—which offers even more insight than the three provided above—on our Circle platform.