Decadal Timeframe for Fusion Pilot Plant IS Achievable - Kyoto Fusioneering Report Insights

By Bibake Uppal, Kyoto Fusioneering America

The pursuit of a net energy-producing fusion plant by the mid-2030s is progressing at full speed. A vibrant industry is now emerging, with coordination between public and private sector and new market dynamics shaping both domestic and international supply chain and fusion development players.

On June 26th, Kyoto Fusioneering (KF) released a report, “Advancing Fusion Technology: Kyoto Fusioneering’s Approach to Accelerating Commercial Viability,” describing in detail its vision for a practical path forward to engineer a fusion pilot plant on a decadal timeframe.

Here we pick out three key insights from the report.

1.Disaggregating fusion plant goals into a hierarchy of functional requirements allows for shared work and reduced risks across the industry, and fosters a resilient ecosystem.

The technoeconomic goals of a fusion plant, which are derived from the National Academy of Science, Engineering, and Medicine’s 2021 report on fusion energy and summarised in Section 1 of KF’s report, can be subdivided into system criteria. These divide further into technology criteria, and then further still into specific scientific criteria.

For example, achieving high efficiency in energy conversion (technoeconomic goal) can be broken down into:

- System Criteria:

- Efficient thermal management

- Reliable energy extraction and conversion

- Technology Criteria:

- Development of high-performance heat exchangers operating at high temperatures

- Advanced materials for thermal cycles resistant to tritium permeation

- Scientific Criteria:

- Understanding heat transfer mechanisms at high temperatures

- Investigating material properties under neutron irradiation and high thermal loads

Note: Simplified for demonstration. See report for elaborated criteria.

Aligning with partners and collaborators on higher order criteria enables a division of labour at lower orders, promoting common challenges to be solved horizontally across the industry. This diffuses financial and technical risk from individual fusion development programmes, while protecting the points of differentiation.

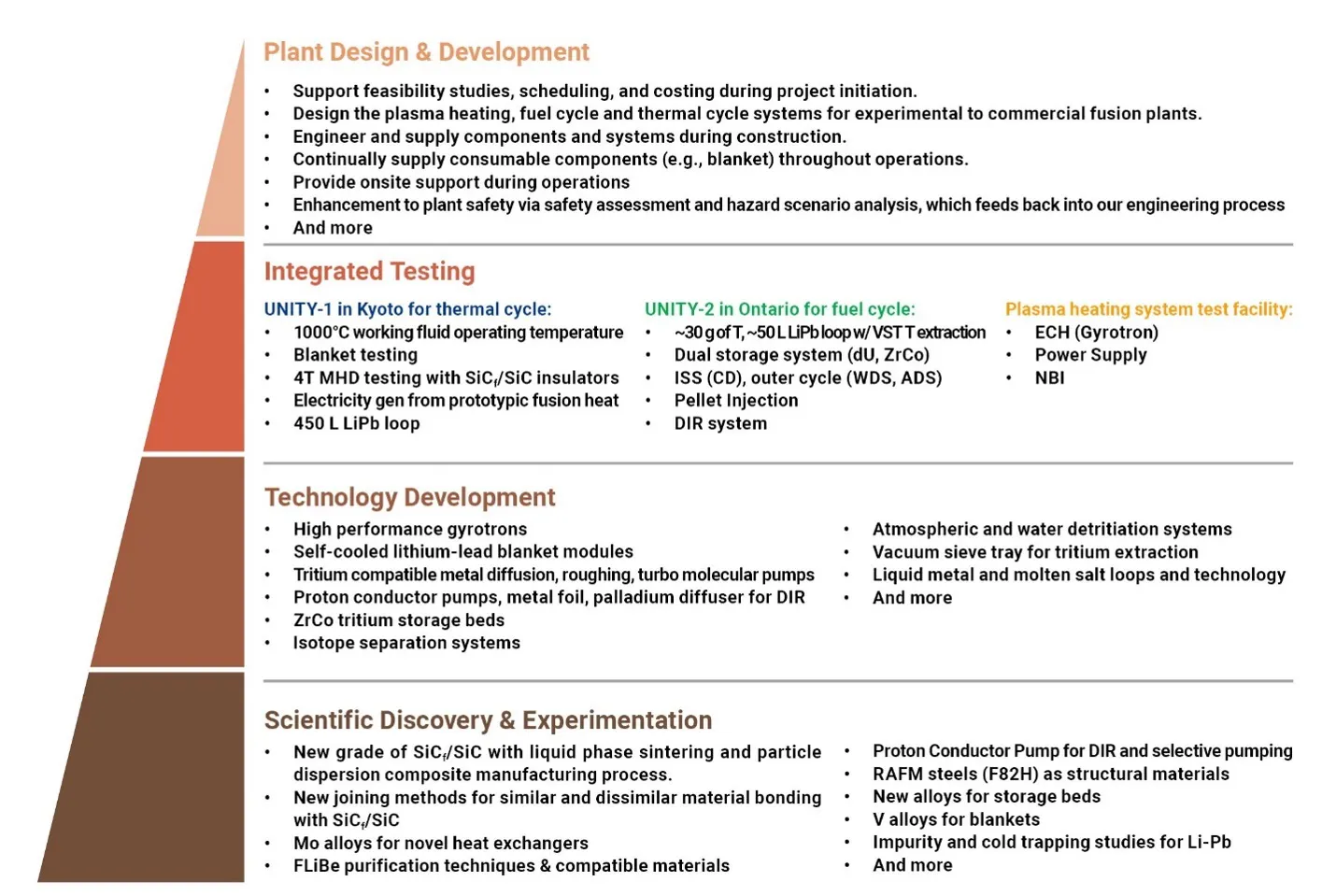

In the spirit of disaggregating functional requirements and distributing the work to promote a resilient fusion ecosystem, Kyoto Fusioneering and its partners design, develop and demonstrate a subset of the key fusion plant systems, relevant across the industry. This is done at each functional level, from science and technology to system integration at the plant level. The diagram below, taken from the foreword to the report, describes some of the activities and technologies under Kyoto Fusioneering’s purview.

The activities and technologies of Kyoto Fusioneering. ©Kyoto Fusioneering

2. A fusion plant design requires a holistic approach from the outset, recognising the interdependencies among complex systems.

The interdependent nature of the required systems in a fusion plant demands holistic design from the beginning. No player in the fusion industry can achieve this alone and Kyoto Fusioneering believes that solving humanity’s greatest challenge requires strategic collaboration. Private sector agility and market forces mitigate the challenges faced by public programmes.

An ecosystem of supporting companies alongside traditional fusion development companies is required to offer critical systems and services. A vibrant ecosystem of such players is emerging already, as evidenced in the recently published fusion industry supply chain report by the Fusion Industry Association.

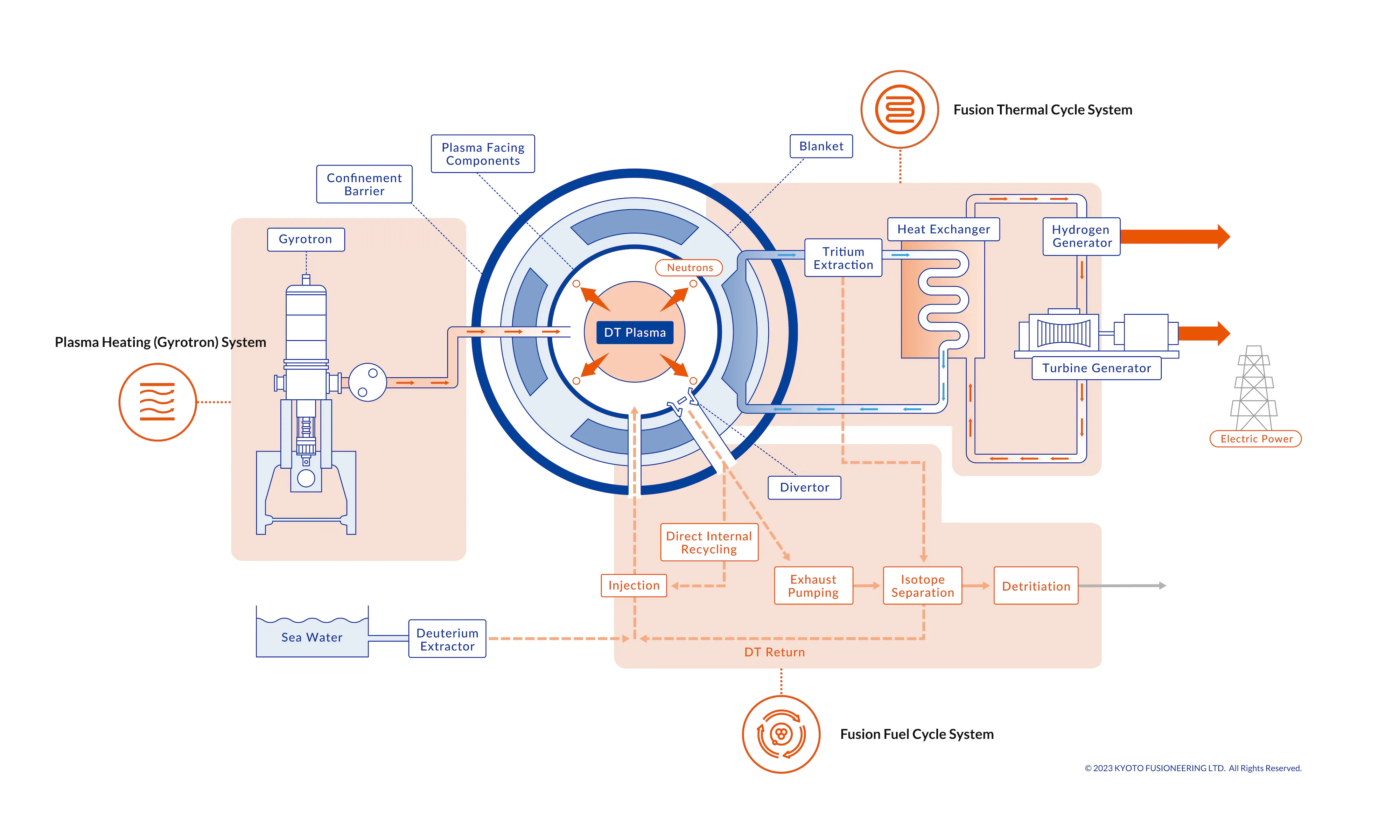

As but one example, KF designs, develops and demonstrates essential systems peripheral to plasma confinement, including the fuel cycle, blanket and thermal cycle, and plasma heating systems. Several niche players innovating on specific technologies within these systems are emerging – a positive trend.

The main fusion power plant systems that Kyoto Fusioneering focuses on designing, developing and demonstrating. ©Kyoto Fusioneering

This holistic approach allows fusion development programmes to concentrate on their areas of strength and within their risk tolerance. Early integration of supporting companies into fusion programmes enables a unified fusion plant design, ensuring all systems meet or exceed performance, economic and safety criteria.

3.Technology gaps need closing to reduce risks for a fusion pilot plant in 2030s—this will require new integrated test facilities, which private companies are delivering.

Alongside the demonstration of a net power producing fusion plasma, surrounding systems must also be demonstrated to be on a path to technical and economic viability.

Though the public sector retains an important role in this activity, novel business models have emerged in the private sector to justify investment and risk tolerance in filling these technology gaps.

For instance, Kyoto Fusioneering and its partners are developing integrated test facilities in Japan and Canada to demonstrate the blanket and thermal cycle, and fuel cycle systems, respectively. These facilities, which will be fully operational by mid-2026, aim to reduce technology gaps and elevate the readiness level of key power plant systems. Demonstrating these systems within the decade allows a risk-reduced path to a net energy producing fusion plant in the mid-2030s.

Further, these unique integrated testing facilities, UNITY-1 and UNITY-2, will serve as test platforms for researchers and technologists from collaborative nations to use as user facilities.

1. UNITY-1: Blanket and Thermal Cycle Testing: Located at KF’s Kyoto Research Center, in Kyoto, Japan, UNITY-1 is a non-radiological test facility focused on the blanket component and thermal cycle systems. It is designed to be capable of high-temperature heat extraction and power generation testing, magnetohydrodynamic testing, hydrogen transport and extraction experiments, and more.

2. UNITY-2: Fuel Cycle Testing: UNITY-2, situated in Ontario, Canada, is being developed through a joint venture between KF and Canadian Nuclear Laboratories, Fusion Fuel Cycles Inc. (FFC). This facility focuses on the integrated Deuterium–Tritium fuel cycle. An active facility, UNITY-2 tests high-performance vacuum pumping, fuel cleanup systems, direct internal recycling, matter injection, and tritium processing technologies, among several other key subsystems. Demonstrating these systems in a prototypic environment ensures that they meet the rigorous standards required for safe, efficient and economically viable operation of fuel cycle componentry in a fusion power plant.

3. UNITY for the Community: The UNITY programme offers platforms to allow various technologies to be tested in a common environment to evaluate performance and suitability for fusion plant integration.

Download Kyoto Fusioneering’s report “Advancing Fusion Technology: Kyoto Fusioneering’s Approach to Accelerating Commercial Viability.”